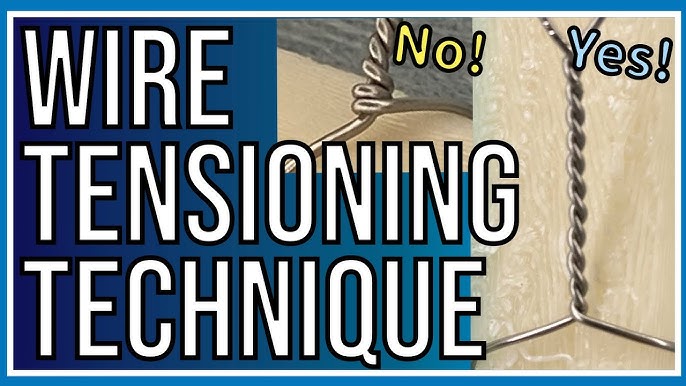

Tensioning Techniques

Understanding Tensioning Techniques: A Practical Guide

Tensioning plays an essential role in many industries, from construction and engineering to fitness and textile work. Learning the right tensioning techniques helps ensure safety, precision, and long-lasting results. This guide explains what tensioning is, why it matters, and how different techniques are applied in real-world scenarios.

What Are Tensioning Techniques?

Tensioning techniques refer to methods used to apply controlled force or tension to a material, cable, rope, belt, or structural component. The goal is to achieve an ideal level of tightness or stability without causing damage. These methods vary depending on the material, required accuracy, and the tools being used.

Why Proper Tensioning Matters

Correct tensioning is important for several reasons:

- Safety: Improper tension can lead to failures, breakages, or accidents.

- Performance: Well-tensioned components work more efficiently and last longer.

- Accuracy: Many mechanical systems rely on precise tension to operate correctly.

- Durability: Properly tensioned materials experience less wear and tear.

Common Tensioning Techniques Used Today

1. Manual Tensioning

This involves applying tension by hand using simple tools like wrenches, levers, or ratchets.

Best for: small ropes, belts, cable ties, and basic construction tasks.

Advantages: cost-effective and easy to perform.

2. Mechanical Tensioning

Mechanical devices apply tension more consistently than manual methods. Examples include screw tensioners, turnbuckles, and pulley systems.

Best for: medium-load applications such as fencing, rigging, and structural adjustments.

Advantages: provides controlled, even tension with less physical effort.

3. Hydraulic Tensioning

Hydraulic systems use pressurized fluid to apply powerful, uniform tension.

Best for: heavy-duty applications such as bolting flanges, installing large cables, and industrial machinery.

Advantages: extremely precise and suitable for large-scale projects.

4. Pneumatic Tensioning

Air-powered tools apply tension with speed and repetition.

Best for: production lines, packaging, and situations requiring quick tension adjustments.

Advantages: fast, lightweight, and efficient.

5. Dynamic Tensioning

This technique adapts tension in real time to handle movement or vibration.

Best for: situations with continuous motion like conveyor belts, exercise equipment, and climbing gear.

Advantages: prevents slack, reduces wear, and improves stability.

Tips for Using Tensioning Techniques Safely

- Always follow manufacturer guidelines for tools and equipment.

- Avoid over-tensioning, as it can weaken materials or cause breakage.

- Inspect ropes, cables, or belts for wear before applying tension.

- Use protective gear when dealing with high-tension applications.

- Recheck tension over time—environmental conditions can cause changes.

Conclusion

Mastering different tensioning techniques helps ensure safer and more reliable results in countless applications. Whether you’re securing a load, tightening a structural component, or adjusting a belt system, understanding the right method makes all the difference. By choosing the proper technique and applying it correctly, you can improve performance, enhance durability, and maintain safety in any project,

FAQ on Tensioning Techniques

1. What are tensioning techniques?

Tensioning techniques are methods used to apply controlled force or tightness to ropes, cables, belts, or structural components. They help ensure stability, accuracy, and safety in various applications.

2. Why are proper tensioning techniques important?

Correct tensioning prevents breakage, equipment failure, and safety hazards. It also improves the performance and lifespan of materials by keeping them at the ideal tension level.

3. What industries commonly use tensioning techniques?

These techniques are widely used in construction, engineering, rigging, manufacturing, transportation, fitness equipment setup, and textile work.

4. What is the difference between manual and mechanical tensioning techniques?

Manual tensioning relies on physical force and simple tools, while mechanical tensioning uses devices like turnbuckles or pulley systems for more precise control and easier adjustments.

5. When should hydraulic tensioning be used?

Hydraulic tensioning is best for heavy-duty or high-precision tasks, such as tightening industrial bolts, tensioning large cables, or working with heavy machinery.

6. Can tensioning techniques prevent equipment damage?

Yes. Properly applied tension reduces strain, prevents excessive friction, and minimizes the risk of sudden failures, extending the lifespan of equipment.

7. Are there risks associated with tensioning techniques?

Risks mainly arise from over-tensioning or using worn-out materials. Both can lead to breakage or unsafe conditions. Using proper tools and following safety guidelines minimizes these risks.

8. Do tensioning techniques require special tools?

Some do. Manual techniques may only need basic hand tools, while hydraulic or pneumatic techniques require specialized tensioning devices for accurate results.

9. How often should tension be checked?

It depends on the application. For machinery or structures under constant stress, tension should be checked regularly. Environmental changes, vibrations, and wear can all affect tension over time.

10. Can beginners learn tensioning techniques easily?

Yes. Many basic techniques are beginner-friendly, especially manual and mechanical methods. More advanced techniques, like hydraulic tensioning, may require training or supervision.